The Crusader self-propelled howitzer was being developed for the US Army as a replacement for the Paladin and the US Army requirement was expected to be for over 800 vehicles.

In May 2002, the Crusader programme was officially terminated by the Department of Defense because it was not considered sufficiently mobile or precise for the evolving security needs of the 21st century.

In August 2002, prime contractor United Defense and major sub-contractor General received the formal termination that ended all further work on the $11bn programme. United Defense was later awarded a contract to use technologies developed for the Crusader programme to produce a lighter and more deployable objective force cannon or non-line-of-sight (NLOS) cannon.

“Objective Force” is the working title for the US Army’s long-term future combat force – the principal modernisation programme that began in 2003. In early 2009, however, Pentagon and army officials announced the cancellation of the future combat systems (FCS) vehicle-development programme. The XM1203 NLOS cannon was planned to be fielded in 2009 as part of the FCS but was cancelled too.

Live firing trials of the Crusader began in February 2000 at Yuma Proving Grounds in Arizona, and in November 2000 a firing rate of 10.4 rounds a minute was achieved. The system successfully completed its preliminary design review (PDR) in November 2001. The first production versions were due in 2006 and it was planned to enter service in 2008. The Crusader programme was being carried out by Team Crusader, led by United Defense.

The Crusader artillery system was intended to provide enhanced survivability, lethality and mobility and be more easily deployable and sustainable than current systems. A battery of six Crusaders can deliver 15t of ammunition in less than five mins.

United Defense reduced the weight and size of the Crusader vehicle from 60t to 38t to 41t allowing two vehicles rather than one to be transported on a C-5 or C-17 aircraft. This allowed the howitzer to be more easily available for fire support missions.

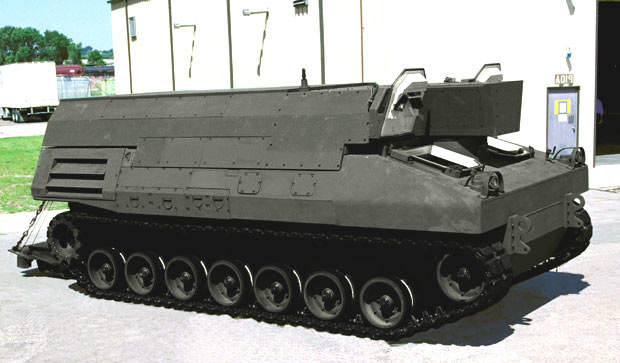

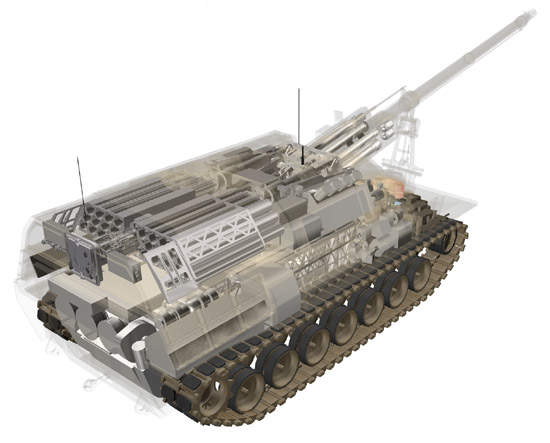

The Crusader consists of two vehicles, the XM2001 155mm self-propelled howitzer and the XM2002 armoured resupply vehicle. The high level of automation means that the howitzer and re-supply vehicle each require only three men to operate it. The gunners can control the entire loading and firing process from the safety of the computerised cockpit under armour and nuclear biological and chemical warfare protection. In addition to the current tracked system, the Crusader armoured resupply vehicle is being offered in a wheeled variant.

XM2001 self-propelled howitzer

Crusader’s 155mm self-propelled howitzer, XM2001, has fully automated ammunition handling and firing that allows firing of the 48 on-board rounds at rates of up to ten rounds a minute to ranges in excess of 40km. The first rounds of a mission can be fired in 15 to 30 seconds. Crusader also has the capability to fire multiple rounds to achieve simultaneous impact on target (MRSI). One Crusader vehicle can fire up to eight rounds to strike a single target at the same time. The digital fire control system calculates separate firing solutions for each of the eight projectiles.

XM2002 resupply vehicle

Crusader is resupplied by the XM2002 ammunition resupply vehicle, which is equipped with a fully automated ammunition handling subsystem. This allows its three-man resupply crew to automatically transfer, under armour, up to 48 rounds of ammunition and fuel to the howitzer in less than 12 minutes. Resupply can be carried out in a contaminated environment.

The resupply vehicle itself can be fully loaded with fuel and 110 rounds of ammunition in less than 60 minutes.

Command and control

Crusader’s command centre is equipped with onboard tactical systems including decision aids, and advanced position and navigational aids and an automated IFF system.

The Crusader sends and receives real-time battlefield information through the advanced field artillery tactical data system (AFATDS) and it can communicate directly with other combat vehicles. The secure data transmission network digitally links the howitzer, resupply vehicle and the rest of the battlefield to give every vehicle real time situational awareness.

Armament

Crusader can deliver any type of round including high explosive, white phosphorus and smoke, DPICM, illumination and SADARM rounds.

The Crusader solid propellant armament system includes the cannon, gun mount, and a laser ignition system. The Crusader cannon tube is integral midwall cooled (IMC) which enables extremely high rates of fire.

The cannon chamber and tube are chrome-plated to minimise wear and erosion. The chamber is compatible with the modular artillery charge system (MACS) solid propellant propulsion system.

Propulsion

The Crusader’s engine and hydropneumatic suspension give a road speed of up to 67km/h and a cross-country speed of 48km/h. The transmission allows automatic scheduling of engine speed and transmission ratio for fuel economy. The driving system features drive-by-wire, positional navigation and movement planning decision aids.

The US Army selected Honeywell International Engines and Systems and General Electric to develop a new LV100-5 gas turbine engine for the Crusader, in common with the M1A2 main battle tank, as part of the Abrams / Crusader common engine programme. The new engine is lighter and smaller with rapid acceleration, quieter running and no visible exhaust.